The Single Best Strategy To Use For gearbox cvt

The Single Best Strategy To Use For gearbox cvt

Blog Article

CVT gearboxes can create a droning noise that holds constant, in place of growing or decreasing with engine pace. This can be a bit disconcerting for many drivers, and can take some finding used to.

Because the CVT isn’t shifting gears, the experience is smoother, which quite a few could choose to the relatively jerky experience of the computerized transmission.

With time, the elements can use down, transmission fluid can become contaminated and software package glitches may well come about, all of which lead to the problems outlined over.

Prospective Brings about: Very low transmission fluid, a failing cooling process, or excessive pressure about the transmission on account of significant driving or towing.

In some ways a CVT gearbox is comparable to a regular car. For starters, there is not any clutch pedal in a CVT-Geared up car, to help you travel it on an automated-only United kingdom driving licence. You will also learn that if a vehicle is obtainable by using a CVT gearbox, Will probably be more expensive than exactly the same product with a manual gearbox, much like a daily car.

This enables the motor to work at its most successful stage, leading to far better fuel economy and smoother acceleration.

Nonetheless, when you rise up to greater speeds (Daihatsu claims in between forty-90% driving pressure in its presentation), the D-CVT shifts into its split mode, engaging the equipment drive that gives a more economical (considerably less energy reduction) indicates of electric power transmission, whilst the rotation to your belt drive is diminished considerably. You may see this changeover involving normal and break up method in a video by Japan’s Internet Cartop

Basically, torque ratios are accomplished if the v-belt rotates within the decreased cross area in the enter pulleys and for the increased cross portion on the output pulley.

This is often why quite a few hybrid drivers prefer motor vehicles with eCVTs for their reduced maintenance and fantastic gasoline efficiency.

Probable Deal with: Change the transmission totally, which may require significant labor and price depending on the extent of your problems.

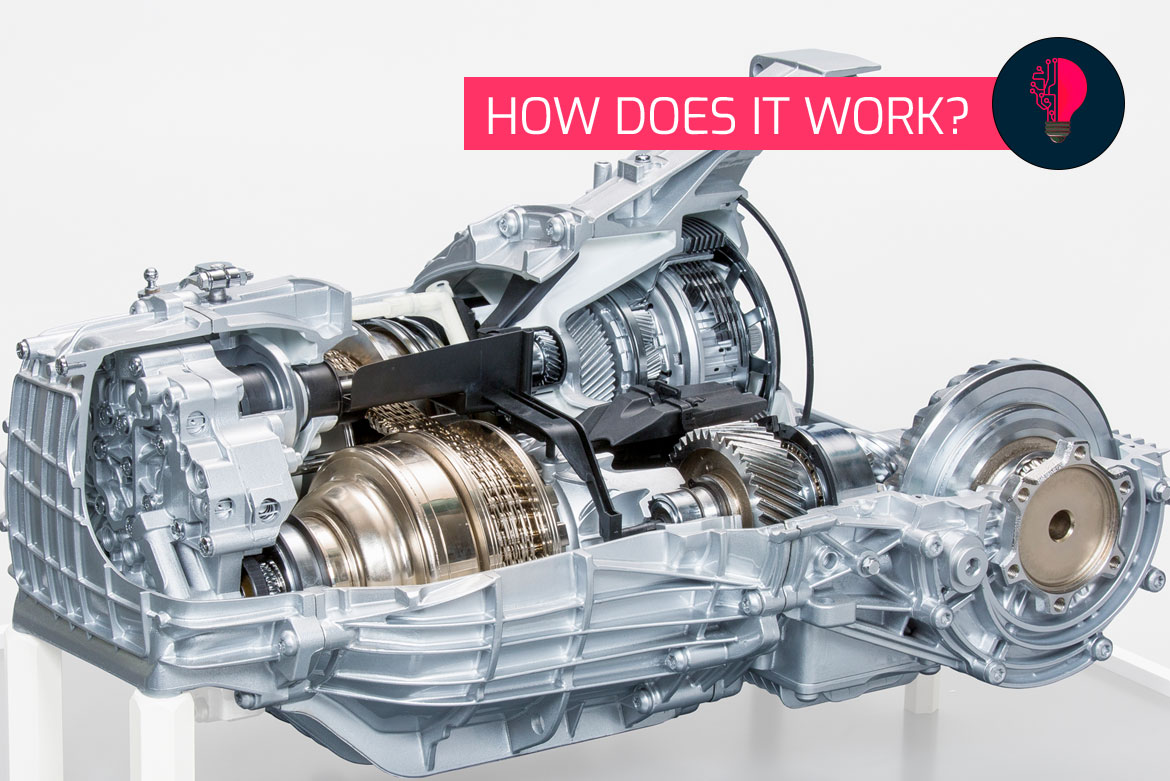

A CVT employs an easy pulley technique rather than the planetary gears that can be found in a conventional automated transmission. The CVT has an enter pulley, an output pulley, and also a belt connecting the two pulleys.

In an average CVT, You can find an input pulley that is linked to the engine crankshaft via a torque converter (or clutch pack) and an output pulley that sends electricity to the wheels. A belt (or chain) connects The 2 pulleys, which often can alter their diameters to deliver an infinite variety of equipment ratios. With no gears, the stepless transmission permits smoother acceleration and efficiency, though getting lesser in dimension compared to transmissions that do have gears. That is a great list of traits for Daihatsu, mainly because it allows for improved packaging in its kei and compact cars. But you can find downsides to a traditional CVT

The generate ratio is adjusted by shifting linkage geometry in the read here oscillating elements so the summed utmost linkage speed is modified, even though the standard linkage speed stays frequent.

The trick is, to be able to sustain belt pressure, The 2 pulleys really have to act oppositely in unison. I guess only one pulley has to be actively assorted, when one other can utilize spring pressure to shut the hole thus sustaining stress.